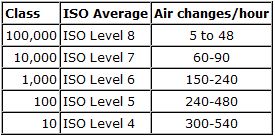

Hardwall modular cleanrooms provide a rigid wall structure and a completely enclosed cleanroom with air vents to exhaust air. These cleanrooms hold higher pressure differentials, which is important to provide differing cleanliness levels in different areas (and which is required to meet FDA 797 requirements). Negative and positive/negative pressure cleanroom designs require hardwall cleanrooms, as do A/C and humidity control cleanrooms.

LCGC LABS fabricates hardwall cleanroom walls from acrylic, static-dissipative PVC, polycarbonate, and polypropylene (all in various colors) with frames of powder-coated steel. In addition, LCGC offers BioSafe hardwall cleanrooms fabricated from 304 or 316 stainless steel.

Softwall modular cleanrooms use a simpler steel frame structure to support flexible PVC (or non-out-gassing Polysym) curtains cut a few inches above the floor to provide an exhaust vent. Softwall cleanrooms provide only the lowest of positive pressures and are typically used only in lower cleanliness ratings such as Class 1000, 10,000 and 100,000. Because these cleanrooms offer less control over air flows, temperature and humidity control are normally not provided.

Smaller softwall cleanrooms can be fitted with casters. Softwall cleanrooms are generally not suitable for complex, multi-room designs and long spans.