Introduction

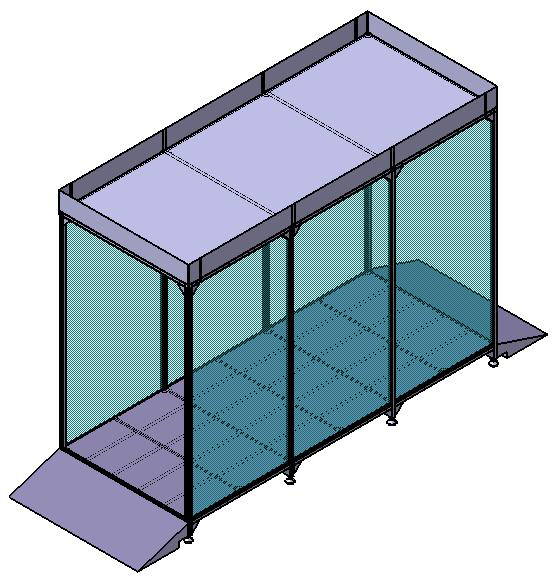

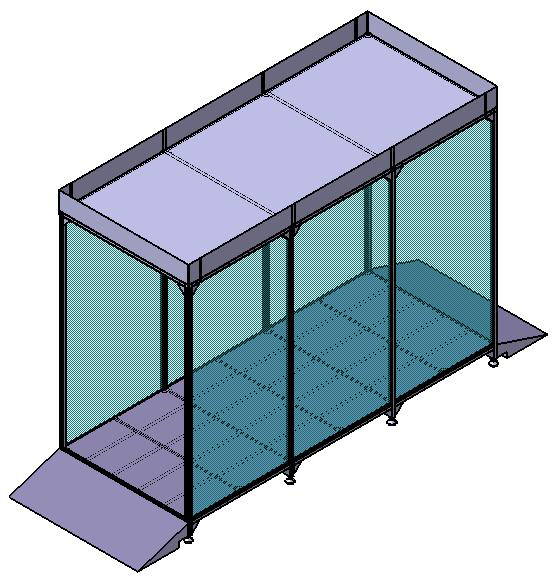

At LCGC LABS, we offer you hi-tech Sanitization Chambers catering to your respective industries. We ensure the cost-effectiveness, design flexibility, and versatility in the cleaning and sanitization for pharmaceutical, medical, manufacturing, and several other industries. Our Portable, expandable, and easy assembling/ disassembling system makes the sanitization chambers even more plausible to all industries.

Description

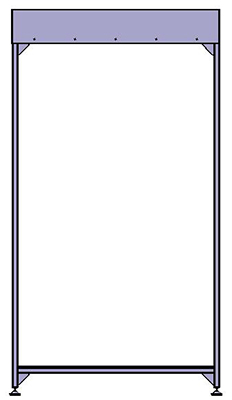

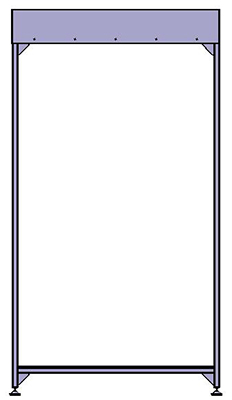

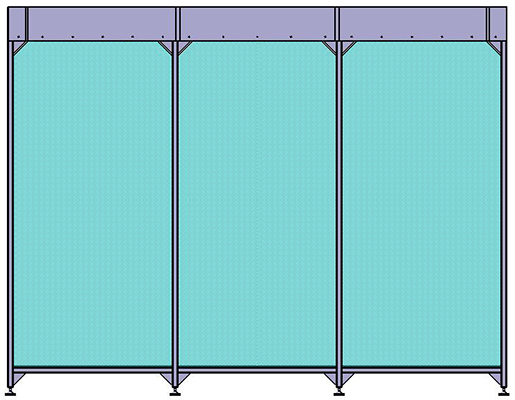

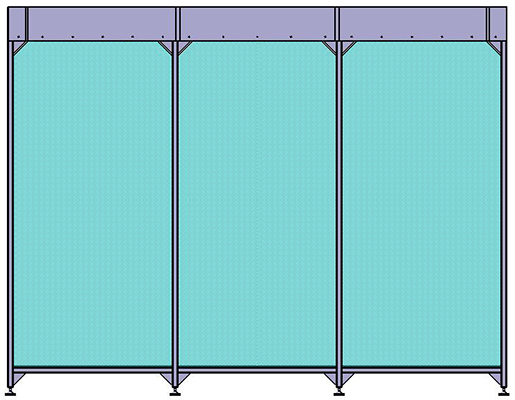

Our sanitization chambers are portable, with sanitizers and soap dispensers at the ready. Upon entering the sanitization chamber, a 25 second calibrated disinfectant mist of hypo sodium chloride is created through an electrical motor pump for disinfection purposes. It automatically indicates the operation completion after 25 secs. The person under disinfection needs to keep their eyes closed for the process inside the chamber.

The steel/aluminum frame with PVC or ESD panels and curtains creates an effective structure of the sanitization chamber. And the design and installations are completely customizable according to your operational requirements.

Object Sanitization Process

- The object will be placed in an enclosed environment with atmospheric pressure

- Chlorine dioxide gas vapor will be provided in the enclosed space, and

- The chlorine dioxide vapor will sanitize the object with uniform pressure.

The chlorine dioxide gas vapor is sprayed from a small pipe with the help of a pump kept on top of the sanitization chambers. Using chemicals like chlorine dioxide is one of the fastest and most efficient ways of disinfection in industrial applications.

Bleach, ethanol, ammonia, hydrogen peroxide, and many others chemicals in a correct concentration can surely kill over 99% of bacteria and be used for sterilization. However, these chemicals may not be compatible with cleaning several industry-grade materials. For instance, some alcohols may cause plastics deterioration with repeated contact. Even paper materials cannot be sanitized with liquid disinfectants.

Even fogging sanitization with hydrogen peroxide can be a safer option compared to highly flammable ethanol or harmful, corroding bleach. Currently, hydrogen peroxide is used to sterilize hospital rooms. But the process is lengthy, with 15-30 minutes for application and 1-2 hours waiting time for safe use. It is an Environmental Protection Agency (EPA) classified as a sterilant.

A 7% H2O2 solution in fogging machines is enough to sanitize a small enclosed area. An enclosed box around the fog machine nozzle creates a greata portable sanitization chamber. This design is swift and efficient in sanitizing some objects without corroding them.

Applications of Sanitizer shower

Sanitizer Shower

Sanitizer shower creates a highly efficient, contaminant-free space in a cost-effective way. Using a sanitizer shower ensures great and thorough disinfection of any object or person with a safe disinfectant.

Use of Sanitizer Showers are in –- Hospitals

- Pharmaceuticals industries

- Government offices

- Police stations

- Army stations

- Corporate offices

- Airports

- Railway stations

- Bus stops

- Public spots

- Malls

- Schools

- Colleges

- Hotels